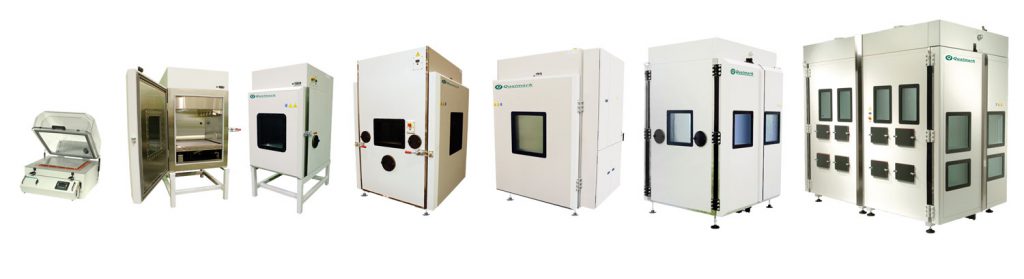

Alphatech is your Trusted Supplier for the Sale, Hire and Service of

Environmental Chambers, Climatic Chambers, Humidity Chambers, Vibration Shakers and Controllers.

Independent UKAS 17025 Accredited Test Lab located near Cambridge, UK.

Sales & Hire

Alphatech are exclusive distributors in the UK and Ireland for Aralab Environmental Test Chambers from Portugal, QualMark HALT/HASS; Sentek Dynamic Vibration chambers from USA; Suga instruments from Japan and Crystal Instrument Data Acquisition Devices & Controllers.

Whatever your product testing requirement, our extensive product range and huge experience will ensure you get the right solution at the right price.

UKAS 17025 Test Lab

We offer a UKAS accredited test laboratory service, performing a multitude of tests both on behalf of our clients and with our clients on-site.

Whether you are in the product development phase of your project and are looking for a lab for development work, or you require compliance testing to national or international environmental test standards, a UKAS accredited test lab will provide key benefits.

Service & Support

Most thermal chambers have heating & refrigeration plant, generally, these are electromechanical plant systems but some use LN2 for extreme low temperatures and/or high rate of change.

Alphatech service personnel are highly qualified & equipped to carry out work on all such systems. We have a range of service plans to suit your testing requirements and budget.

ALPHATECH MISSION STATEMENT

“We value quality of products and services. Alphatech always has and always will strive to exceed our customer’s expectations and aim to achieve excellence”

Test Services Offered by Alphatech

Our Latest News

Cold Storage Testing

From supermarkets to restaurants, refrigerated display cabinets are essential for keeping food fresh and safe. Aralab’s walk-in test chambers are designed for assessments under the ISO 23953-1:2015 standard and excel in cold storage solutions testing. [...]

Aralab TESTA 1000 Solar Radiation chamber

In a warming world, it more important than ever that manufacturers test their products for the effects of prolonged exposure to sunlight. Designed to simulate temperature, climatic conditions, and irradiation, the TESTA 1000 Solar [...]

Lithium Battery Safety Testing

Rechargeable Lithium Batteries have become the most popular form of energy storage for portable electronic devices, electric vehicles and bicycles, military equipment, etc. Reliability and safety are crucial. The batteries must perform well in hot [...]